Products

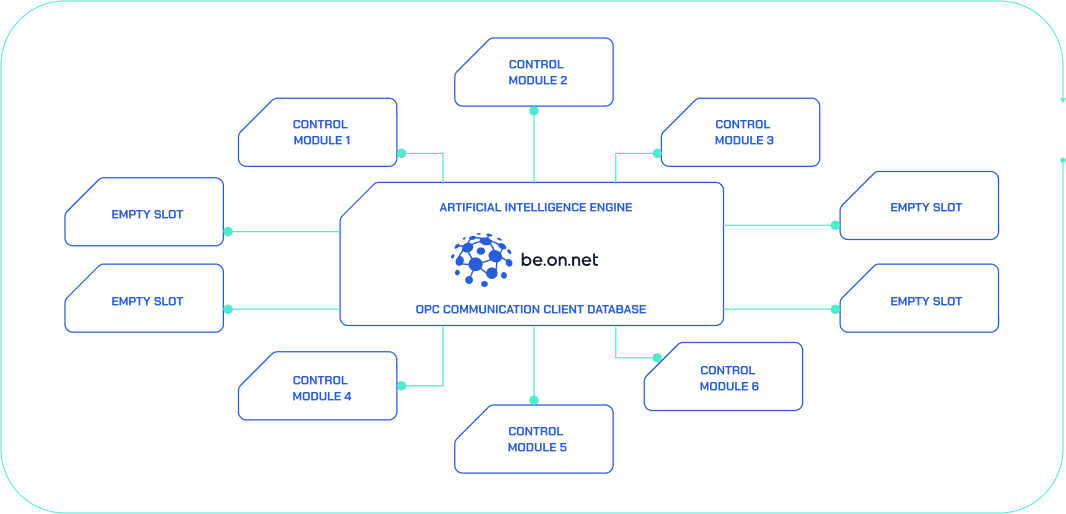

The be.on.net platform is a client-server software application. It represents the basic software package necessary for all be.on.net functionality and can be used for modelling and control of different processes depending on the integrated control modules. The be.on.net platform is based on one server application which is used to provide full expert system and communication functionality. The client application is used as a graphic user interface for configuring and monitoring the be.on.net expert system. There can be an arbitrary number of client applications. User policy management is used to set the privileges and functionality of each user in the client application.

Modules

The be.on.net modules are advanced control modules for specific purposes.

The number and type of control modules deployed on the platform are not limited

and are specified by the number of processes controlled by the be.on.net.

Cement industry modules

Preheater

Energy Control

By regulating fuels and overall energy input in the preheater, advanced features of be.on.net are able to handle any process disruption and to keep process and production on a stable and optimal level. This allows for a further increase in alternative fuels in the combustion process, thereby reducing production costs and CO2 emissions.

15%

increased useof alternative

fuels achieved

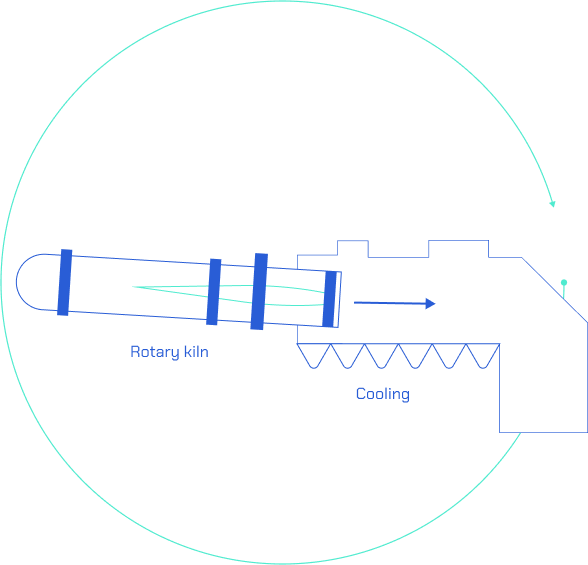

Main Burner

Energy Control

be.on.net continuously assesses the combustion conditions of the cement kiln and regulates the fuels of the main burner to maintain optimal operation. Energy consumption is continuously maintained at the optimal level, with the possibility to maximize the use of alternative fuels which has a significant effect on energy costs and CO2 emissions.

1%

less energyconsumption

measured

Cooler energy

recuperation module

Maximum energy recovery from the cooler is obtained through direct control and optimization of the secondary gas temperature. Such an advanced control strategy is enabled by the unique characteristics of be.on.net and is not technically achievable using other traditional control systems. Energy savings and reduction in carbon emissions are easily computable.

2%

less energyfor each

ton of clinker

Cement grinding

and energy reduction

Grinding Process module

be.on.net control optimizes the production ratio and the quality of the product at the same time. This control strategy is superior to the traditional strategy commonly used in the industry, and can provide 3% to 10% higher performance and 30% better consistency of fineness.

10%

higher output

Cement Strength

Prediction Module

be.on.net integrates all product sample data and predicts cement strength for all standardized time periods. This allows continuous and much better cement quality control, leading to significantly reduced time for corrective actions. As a result, the use of clinker and cement components in cement can be optimized, resulting in a significant reduction in CO2 emissions.

98%

provenprediction

accuracy

Custom

module

Users can innovate and create customized modules that match the needs and features of their manufacturing process. The simplicity of use and the various setting options stimulate creative thinking.